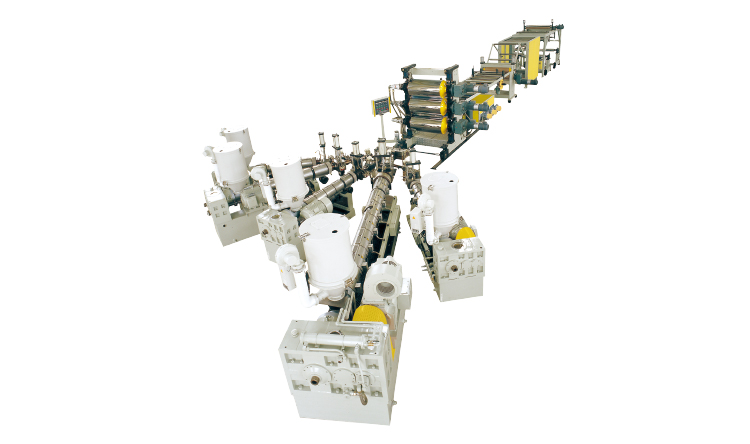

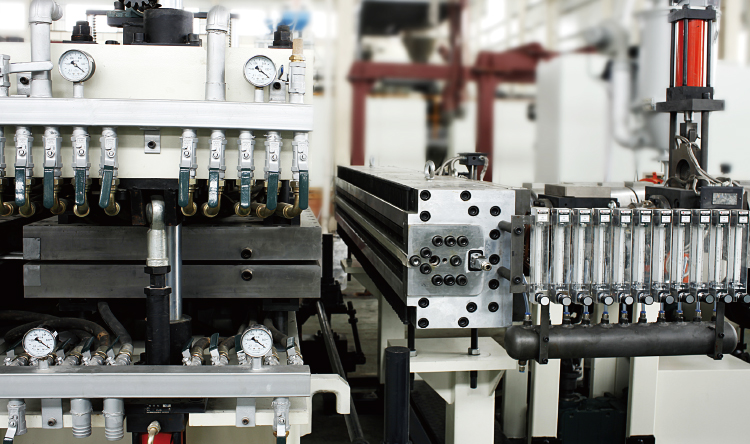

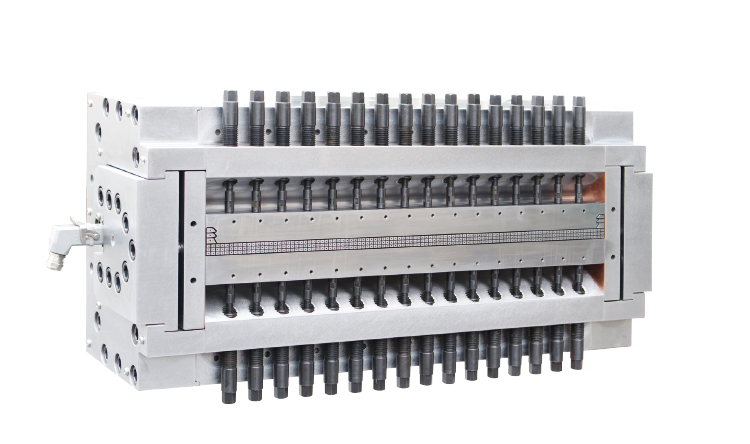

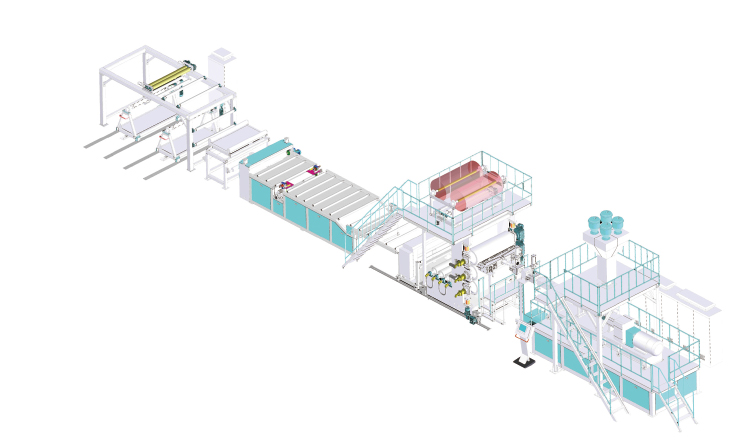

PC/PMMA/GPPS/ABS plastic sheet production line

PC/PMMA/GPPS/ABS plastic sheet production line

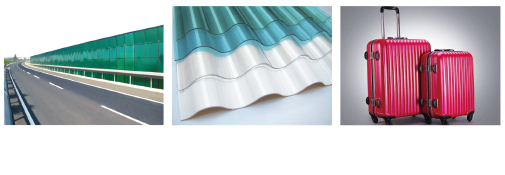

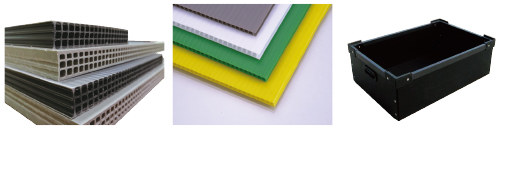

PC Endurance Board, Wave Board

Scope of application: The Garden, the Amusement Place Strange Decoration and the rest place porch pavilion; the commercial building interior and exterior decoration, the modern city building curtain wall; Transparent Air Containers, motorcycle windshields, aircraft, trains, ships, cars, automobiles, submarines and glass military and police shields; Phone Booth, Advertising Road Signs, light box advertising display display display display layout; Noise barriers on expressways and urban viaducts.

ABS, HIPS/GPPS Refrigerator board

The utility model is mainly used for the door and gallbladder of the refrigerator, the inner liner, the drawer, the water receiving plate, the water dispenser, etc. .

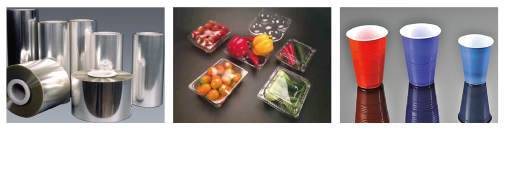

ABS/PMMA Sanitaryware plate Composite Sanitary Board

For sanitary products such as: Bathtub, shower room, steam room, Sink./n/n

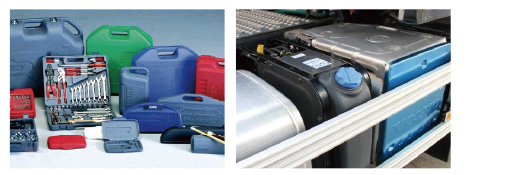

ABS/PC Baggage plate Composite Board

Mainly used for all kinds of luggage, luggage, leisure bags and so on.

ABS、ABS + PC Car plate Alloy Sheet

Main uses: Car Roof, Instrument Panel; seat panel, door panel, window frame; motorcycle, dune buggy, Scooter, golf cart and other shell.

| Model | JWS130/38-2200 | JWS120/38-1400 |

|---|---|---|

| Material | PC, PMMA, GPPS, ABS | PC, PMMA, GPPS, ABS |

| Products Width | 2200mm | 1400mm |

| Products Thickness | 1.5-10mm | 1.5-10mm |

| Extruder Specification | Ø130/38;Ø45/30 | Ø120/38 |

| Capacity (Max.) | 550Kg/h | 450Kg/h |

| Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements. | ||