PET/PLA/CPLA Environmental Protection Sheet production line

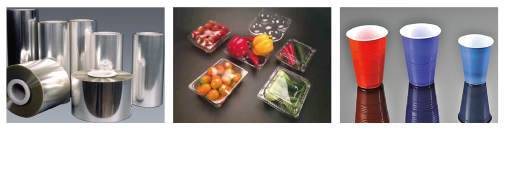

The twin-screw dryer-free exhaust type PET/PLA sheet production line has the advantages of low energy consumption, simple process, convenient operation and maintenance of equipment, and its unique screw combination structure effectively reduces the viscosity reduction of PET/PLA resin, the symmetrical thin-wall roller improves the cooling efficiency and improves the productivity and sheet quality. The multi-component feeding device can reasonably control the proportion of new material, return material, color masterbatch, etc. , the sheet can be used in the fields of blister printing and packaging.

| Model | Extruder model | Products thickness(mm) | Main motor power(kw) | Max extrusion Capacity(kg/h) |

|---|---|---|---|---|

| Multi layer | JWE75/40+JWE52/40-1000 | 0.15-1.5 | 132/55 | 500-600 |

| Single layer | JWE75/40-1000 | 0.15-1.5 | 160 | 450-550 |

| Highly-efficient | JWE95/44+JWE65/44-1500 | 0.15-1.5 | 250/75 | 1000-1200 |

| Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements. | ||||