The large diameter 2m PE thermal insulation pipe extrusion line produced by Shanghai Jwell Pipe Equipment CO.,LTD is taking the lead in the industry. The design is unique and novel, adopting high efficiency single screw extruder, with high level automation, which could meet easily operation, continuous production, stable and reliable. 一、JWELL thermal insulation pipe extrusion line performance.

(1) The extruder adopts high efficiency single screw extruder, and imported foreign advanced technology. The drive motor and Siemens PLC processor could ensure the stable and reliable of equipment’s operation. The extruder’s temperature control system using Siemens PLC control system and extension modules, the temp accuracy could be controlled between ±0.5℃.

一、JWELL thermal insulation pipe extrusion line performance.

(1) The extruder adopts high efficiency single screw extruder, and imported foreign advanced technology. The drive motor and Siemens PLC processor could ensure the stable and reliable of equipment’s operation. The extruder’s temperature control system using Siemens PLC control system and extension modules, the temp accuracy could be controlled between ±0.5℃. (2) Mold

(a)The mold is spiral structure, using high quality alloy steel, with chrome treatment.

(b)The mold core’s temperature control adopts electric heating, that the temp accuracy is high, and the oil copper pipe won’t have carbon.

(c)There are many heating zones, which could control the temperature of each area of mold.

(2) Mold

(a)The mold is spiral structure, using high quality alloy steel, with chrome treatment.

(b)The mold core’s temperature control adopts electric heating, that the temp accuracy is high, and the oil copper pipe won’t have carbon.

(c)There are many heating zones, which could control the temperature of each area of mold. (3)The vacuum calibration tank and cooling tank using the material of stainless steel, water jet cutting, block design. The nozzle using the quickly changeable joint, which could more easier to clean and change, that have overcome the problem of difficult disassembly of fixed installation.

(3)The vacuum calibration tank and cooling tank using the material of stainless steel, water jet cutting, block design. The nozzle using the quickly changeable joint, which could more easier to clean and change, that have overcome the problem of difficult disassembly of fixed installation.

(4)The caterpillar type haul off unit has the advantage of easy operation, less scrapped pipe, strong traction and smooth operation.

(4)The caterpillar type haul off unit has the advantage of easy operation, less scrapped pipe, strong traction and smooth operation. (5)The cutter’s feeding rocker using steel structural component, which has high strength and durable in use.

(5)The cutter’s feeding rocker using steel structural component, which has high strength and durable in use. 二、The character of PE thermal insulation pipe

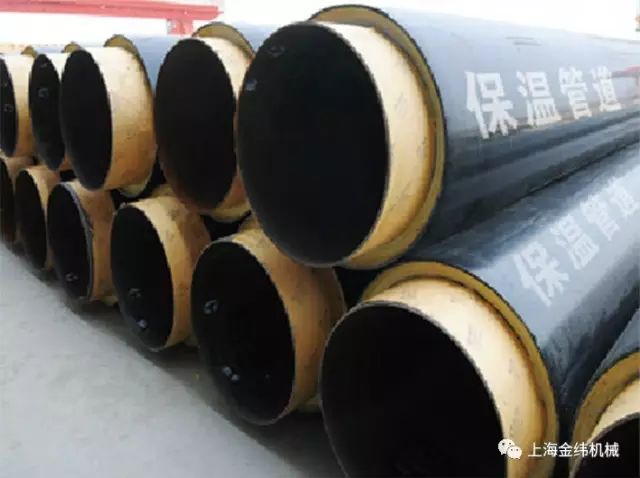

Widely used in liquid/gas pipeline network, chemical pipeline thermal insulation engineering petroleum、chemical、central heating network、central air-conditioning’s ventilating pipe and municipal projects, etc.

二、The character of PE thermal insulation pipe

Widely used in liquid/gas pipeline network, chemical pipeline thermal insulation engineering petroleum、chemical、central heating network、central air-conditioning’s ventilating pipe and municipal projects, etc. (1)Low cost.

(2)Less land occupation, fast construction, good for the environment protection.

(3)Jacket pipe could save energy, anti-corrosion, have good insulation performance and long working life.

(4)There have leakage alarm lines, which is safe. Once there was leakage in somewhere of pipe, by the transmission through the alarm line, could show the accurate leaking location and degree of leakage on the instrumentation, and inform the inspector to deal with the leaking pipe quickly, to confirm the safe operation of heat pipe network.

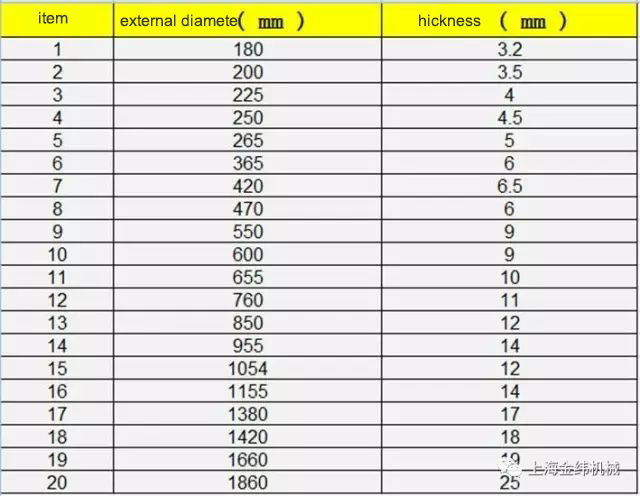

三、Common specifications of thermal insulation pipe

(1)Low cost.

(2)Less land occupation, fast construction, good for the environment protection.

(3)Jacket pipe could save energy, anti-corrosion, have good insulation performance and long working life.

(4)There have leakage alarm lines, which is safe. Once there was leakage in somewhere of pipe, by the transmission through the alarm line, could show the accurate leaking location and degree of leakage on the instrumentation, and inform the inspector to deal with the leaking pipe quickly, to confirm the safe operation of heat pipe network.

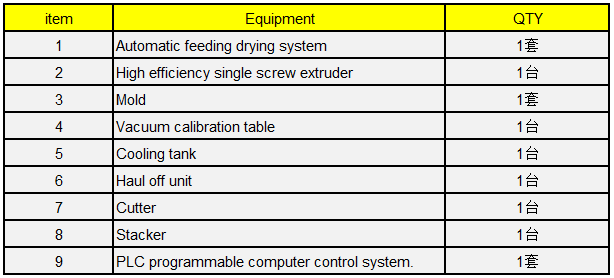

三、Common specifications of thermal insulation pipe 四、 Production line

四、 Production line